Resurrection of Childhood Memories

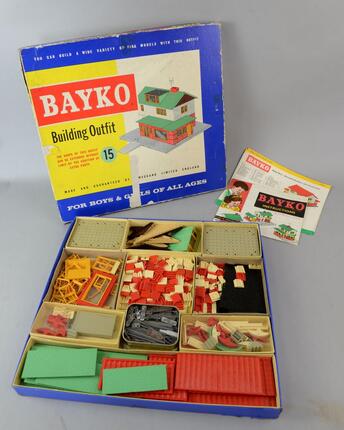

As a Child I remember my father giving me a present of a Bayko set, I believe it was a set 15, or 14 and 14C. I think it must have been a sale or surplus stock as this was around 1962 when I believe Meccano were actually phasing the product out. Either way, I enjoyed playing with the set, making buildings that I could use to play with my Corgi and Dinky car collection. Years go by and I forgot all about Bayko and Corgi until I saw that the cars were being re-issued, and discovered Bayko on EBay, and nostalgia gripped me.

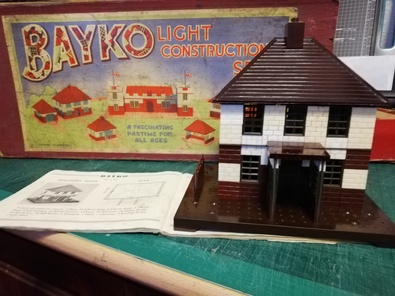

I was pleasantly surprised to find a following of Bayko still going strong. Not only that, but I discovered the pre 1960 Bayko kits which looked more familiar to me as I grew up in a house with similar design to the kits. So, for a reasonable price I managed to get Bayko to build a row of houses which I could use to compliment my car collection.

I kept to the suggestions in the manuals while I came to grips with the process of building houses with Bayko. Below are the fruits of my initial labour.

It was during this collecting that I came across brown Bayko sets which I thought might add variety. However I soon found that the cost of these pre WW2 sets to be very expensive, especially on EBay where even an incomplete set #1 can run over £150.00, not to mention the 'Oak' variety sets which fetch even more money!

While ruminating over this I read about Bayko Club members who had cast their own parts, and since I used to cast chess pieces from resin, and casted plaster brick tiles for Tudor-style doll's houses when I was younger, I decided to have a go at building up my brown brick collection by casting my own bricks.

Having found suitable materials on the internet, I placed my order for silicon rubber to make the moulds, and Polyurethane resin and pigments. Since the early bricks were of a simple design, I decided to make the moulds in one part and pour the resin in from the top.

The process of mixing the resin, getting the colour ratio correct is quite messy. I was consigned to the shed in our back garden after attempting to make a few castings in the comfort of the kitchen table.

The results can be seen in the picture to the left. In the centre is an original Bayko tile, with four castings around it. Although they didn't have quite the shine of Bakelite, the castings do give a good alternative to the originals when mixed in together

I finally found a mixture which, in my humble opinion was close enough to the original Bakelite brick colouring....

Can you spot the original brick?

(Hint: Not in the middle)

The bricks need a little finishing off, like having flashing trimmed off, then the end made flush with a sanding disc, and finally a little polishing, then they are good to go.

Doors are reproduced in the same manner, but with different colouring of course, but casting your own parts opens up the possibility of different coloured doors (blue, purple, orange, whatever your taste), instead of the standard olive, green or yellow.

My attempt at casting windows met with limited success as I tried to use a one piece mould. The really need to have two part moulds so the two parts can be easliy separated to retrieve the casting.

This method of creating new parts has been useful in my first large project — The Royal Clarence Hotel